With the rapid development of China’s reducer market, domestic manufacturers, through large-scale production and process optimization, can now provide products with lower prices but reliable quality. This means manufacturing enterprises no longer have to make difficult trade-offs between performance and cost. So how can enterprises take the initiative to find truly value-for-money options? Let’s look at the 5 core selection criteria for cost-effective planetary gear reducers.

Criterion 1: Look beyond the price to clarify core parameters

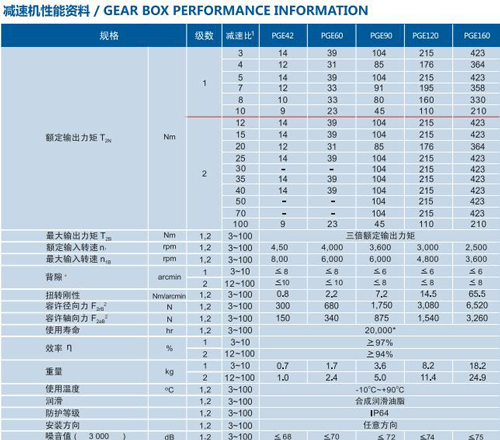

Compare key indicators such as rated torque, instantaneous peak torque, backlash grade, and efficiency.

Criterion 2: Request and verify test reports

Formal manufacturers should all provide factory test reports. Pay attention to data on noise, vibration, efficiency, etc. This is the “physical examination report” of product performance.

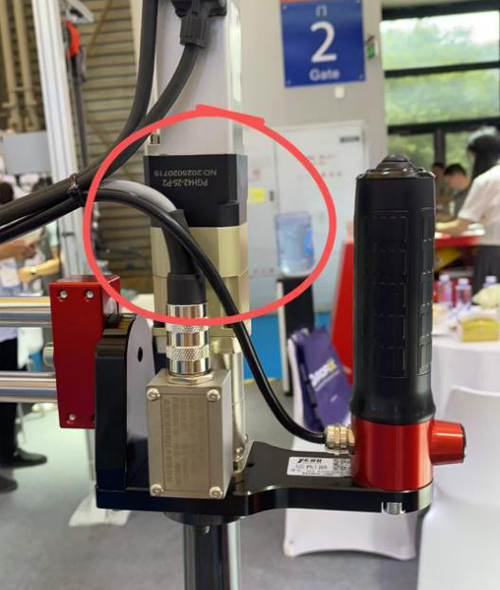

Criterion 3: Evaluate the manufacturer’s strength and real cases

Does the manufacturer have successful industry application cases? The picture below shows the on-site application of our reducer in an industrial machine of a mainstream brand, which has been operating stably for over 10,000 hours.

Criterion 4: Confirm the ease and standardization of installation

Do the interfaces comply with international standards such as ISO? Can they be quickly adapted to the servo/stepper motors you commonly use? This can save you valuable installation and commissioning time.

Criterion 5: Assess long-term service commitments

Clear warranty terms and fast technical support channels are key to reducing your long-term operational risks.

In Qiandeyi’s view, true cost-effectiveness is by no means at the expense of key performance and long-term reliability. Instead, under strict cost control, it still provides you with stable, durable, and easy-to-use products, as well as timely, reliable, and reassuring services. Take action now and let professionalism be your strongest backing for cost reduction and efficiency improvement!