In the field of precision transmission, the harmonic gear reducer serves as the “core joint” of industrial robots and high-end equipment, playing a decisive role in the overall performance and market competitiveness. Whether it’s an industrial robot carrying out precision assembly or a service robot achieving dexterous operation, the harmonic gear reducer ensures every movement is accurate with its ultra-high precision transmission, zero backlash response, and strong load-bearing capacity. Without the harmonic gear reducer, robots would lose their “flexible joints” and “stable power”, making it difficult to perform complex tasks and unable to meet the stringent requirements of modern industries for the efficiency and precision of robots.

QianDeYi harmonic gear reducers have made a strong breakthrough in the global market with their ultra-high precision, superior durability, and excellent cost-effectiveness. Their products have precision comparable to international big brands, but the price is 30% lower. Many industrial robots and automated production lines at home and abroad have chosen Qiandeyi harmonic gear reducers. Not only do they have stable performance, but they also come with a complete after-sales service, truly achieving cost reduction and efficiency improvement.

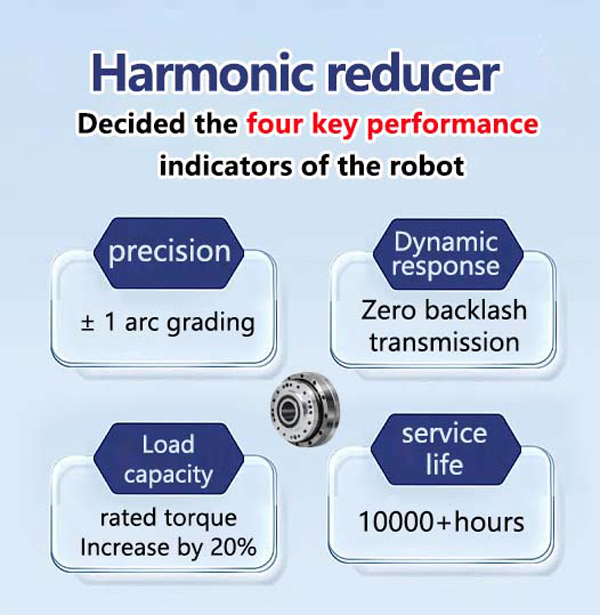

1. Ultra-high Precision Transmission

Using flexible gear meshing technology, the transmission precision is ≤1 arc minute, far surpassing traditional gear reducers. It is a perfect fit for high-precision scenarios such as joints of industrial robots, precision machine tools, and semiconductor equipment.

2. Lightweight Design

With a compact structure, the weight is only one-third of that of planetary gear reducers, significantly reducing the load of equipment and helping collaborative robots, AGVs, and aerospace equipment achieve lightweight upgrades.

3. Zero Backlash & High Rigidity

There is no gear clearance, resulting in a faster response speed. The torsional rigidity is as high as 45N·m/arcmin, meeting the stringent requirements of industrial robots, medical equipment, and automated production lines for high dynamic performance.

4. Extra-long Service Life

Made of special alloy steel and using advanced lubrication technology, the service life exceeds 10,000 hours, and the maintenance cost is 40% lower than that of traditional gear reducers, ensuring long-term and stable operation.

All products have passed the ISO9001 certification. A senior R&D team of over 50 people can provide customized solutions with high precision, high rigidity, and low noise according to the usage scenarios of the equipment, fully escorting the implementation of customers’ projects.