Against the backdrop of diversified applications of RV reducers, bulk product solutions are becoming an important option to meet the needs of specific scenarios. The structural design of RV reducers fully considers the flexibility of system integration. Their core components adopt a modular design concept, supporting multiple input and output configurations:

Input methods: four modes including hole input, shaft input, extended shaft input, and extended flange input.

Output forms: four combinations including hole output, unidirectional shaft output, bidirectional shaft output, and flange output.

This modular feature enables equipment manufacturers to flexibly select the most suitable interface methods according to the spatial constraints of mechanical structures and functional requirements. For example, in space-constrained AGV drive units, a compact configuration of flange input + bidirectional shaft output can be chosen; while in large welding positioners, a high-rigidity combination of hole input + flange output can be adopted.

Bulk RV reducers provide equipment manufacturers with space for in-depth customization. Qiandeyi ATG’s product series covers a center distance range from 25 to 185mm, with single-stage reduction ratios ranging from 5 to 100 in multiple gears. Two-stage combinations can achieve an ultra-low output speed of 710. This flexible combination method allows customers to avoid paying additional customization fees for special parameters, significantly reducing equipment development costs.

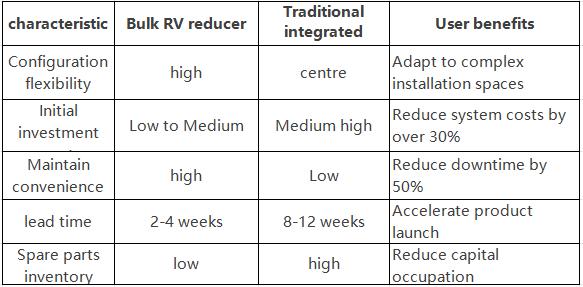

More importantly, the bulk supply mode enables equipment manufacturers to optimize inventory structures. Traditional complete machine manufacturers usually need to stock various models of complete reducers, but with the bulk solution, manufacturers only need to reserve core RV modules, paired with self-designed frames and drive units, greatly reducing inventory capital occupation. Practice has proved that manufacturers adopting bulk RV solutions can save more than 30% of transmission system costs while shortening delivery cycles by 50%.

Qiandeyi ATG’s new-generation RV reducer platform integrates three major technological breakthroughs: materials science (nanostructured gear steel), precision manufacturing (full-closed-loop gear grinding technology), and intelligent monitoring (built-in sensors). We sincerely invite equipment manufacturers from various industries to jointly explore the innovative applications of RV reducers.